Standing in your garage with a dead lawn mower, a phone browser open to Google, and the vast untamed landscape of small engine troubleshooting before you, it can be easy to get discouraged. After all, just about anything that prevents a lawn mower from running well can also prevent it from starting. Let’s simplify all these possibilities and zero in on common starting problems, and ones that you’re likely encountering.

Of course, your situation could include all manner of devices thought of as “mowers.” You could have a simple push mower, or maybe an electric start push mower. But, you could also have a riding mower, an electric mower, or a zero-turn mower that costs more than a Chevrolet Spark. You might even have a tractor towing a rotary cutter like a Bush Hog, in which case you’re probably not reading this article. We’re going to take a look at the most common: push mowers and riding mowers. Your electric mower is essentially always started, and your licensing agreement might prohibit your working on your own tractor. We also won’t deal with zero-turn mowers directly, but obviously a lot of the info for small engines in general will apply to zero-turns. Let’s dive into some of the reasons your mower may not be starting, and what you should do about it.

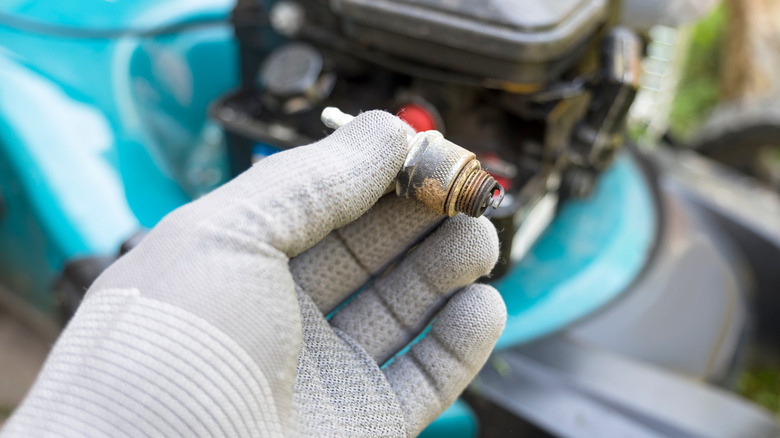

Ignition system problems: spark plugs

At some point — possibly when the words “we have ignition” from the Kennedy Space Center Firing Room — many of us began to think of the word “ignition” as synonymous with “starting,” but that’s not exactly what’s going on with ignition systems. An ignition system is actually about producing a spark that ignites a fuel-air mixture within an engine’s cylinder(s). Ignition happens continually when you’re using a mower. A few components of this system can be culprits when an engine won’t start.

The most common culprit is probably a spark plug that needs cleaning or replacement. Buildup from a constantly exploding engine cylinder will eventually degrade the performance of the plug until it can’t function properly at all. It’s a little easier to diagnose a bad spark plug in an engine that will barely start than one that won’t start at all, and if you’ve recently noticed that your mower makes you pull the starter rope harder, is prone to losing power while running, or starts using more gas than normal, the plug might be the problem. The clearest sign of plug trouble is when your engine will turn over but not actually start.

It’s a good idea to replace them at least once per year, and cleaning or replacing your plugs is a reasonable first step in resolving just about any starting problem. You can try gently cleaning a spark plug with fine-grit sandpaper, a file, or a soft wire brush, and you can use carburetor or plug cleaning spray to help. Just be gentle; damaged plugs will not be kind to your engine. There are other potential plug issues (wrong plug, bad gapping, or a cracked insulator) that might not be worth diagnosing, given that replacing the plug with a new (and correct) one addresses all these issues at once.

Ignition system problems: plug wires and coil

After dealing with the plug, it’s just about time to get serious with your diagnostics. But first, inspect your plug wires for obvious wear or damage. If they appear to be in poor shape, they probably are, which makes replacing them a good idea regardless of whether they are the full cause of your starting troubles. Next, it’s time to verify that your engine isn’t getting a spark. Ground your plug’s threads against a metal part of the engine itself and have someone attempt to start the mower as you observe the plug. If you consistently don’t see a spark, you should start looking at other possible causes.

If your plug wires are in good shape, ensure they’re making good contact with the spark plugs. Clean their terminals and, if necessary, squeeze the terminals slightly with pliers. If your mower has an on/off switch, use an electrical tester to make sure it’s functioning. Switches on mowers with pull cords can be slightly tricky to diagnose, so it might be a good idea to check the on/off function with a multimeter set to continuity mode. The point is that the continuity should change when the switch changes from on to off; some switches might close a circuit when on while others might open the circuit, but there should definitely be a change when the switch, well, switches. Check that the coil control wire connecting the engine to the coil isn’t abraded; if it shorts to the engine, the mower won’t start or run. Finally, consider replacing the coil. These are not user-serviceable, but they are affordable and critical to starting and running your mower.

Batteries die for a living

ALPA PROD/Shutterstock

By far the most common element of the ignition system that can prevent a riding mower’s starting is the battery. Almost 20% — 11.8 million — of Google’s search results for the word “battery” include the phrase “dead battery,” because that’s what batteries fundamentally do: expend all their energy and “die.” And lawn mower batteries are almost always flooded lead acid batteries, which die more easily and more thoroughly than any other sort.

A lot of the work of fixing a battery problem is the same as properly maintaining the battery to begin with. That is, it’s stuff you should do regularly anyway. So, clean the battery terminals with a wire brush (clamp-on terminals might require a special type of brush, often cone-shaped). Use battery terminal cleaner if it’s necessary, though it rarely is. Make sure all electrical connections are clean and tight. Batteries that haven’t been maintained with a trickle or smart charger while in storage, such as over the winter, will probably need to be charged and will sometimes even need to be replaced. If your battery is in good condition, check out your alternator and starter. Testing an alternator is simple on equipment with working headlights, as many riding mowers have. Just observe the lights. If they don’t dim when you turn off your engine, you probably have an alternator problem.

After verifying that you have a fully charged battery and a working alternator, check all the wires connected to the alternator and starter for damage. (You can test them with a multimeter if you’re suspicious of their condition.) If everything else checks out, test your solenoid and starter switch using the procedures outlined in this Briggs & Stratton guide.

Fuel troubles

SergeyYrev/Shutterstock

Every now and then you’ll see news about a possible “perpetual motion machine” devised in a scientist’s lab (or mind), but until you can pick one up at Home Depot, you’re going to be dealing with fuel for your lawn mower. This usually means gasoline, and there are a few common points of failure small engines can experience when trying to get fuel from the tank to where it’s needed for internal combustion.

First, make sure you have gas in the tank to begin with. This gets overlooked more often than you might guess, especially when you’re already half-expecting other mower problems and your brain primes the pump by framing everything in that context. Next, examine the age of the gas in use. Did you buy the mower used? Has it been in storage for more than a couple of months? Has the gas itself been sitting in the gas can for a while? Gas can go south in as little as a month, so if someone’s telling you it can sit for two years (a common number in mower lore) without chemical assistance or consequence, you should take your maintenance advice from someone else.

Mowers should be stored without gas or with an added fuel stabilizer (the aforementioned “chemical assistance”), to prevent such issues. Old gas clogs and damages fuel lines and carburetors, and won’t start an engine very well even if it makes it to the right place. If you already have old gas in your mower, you might need to remove and clean the fuel system components, as described here by Simple Green.

Fuel troubles: the fuel system

Lost_in_the_Midwest/Shutterstock

Replace your fuel filter regularly, especially if you’ve had old gas in your engine. If your engine has a fuel pump — and it probably does — it will reside between your fuel tank and the carburetor. When you’re out of options, check that it’s actually pumping by using a guide, like this one from Hello Practical.

There’s also the possibility that you aren’t availing yourself of some aids many lawn mowers have built into them to ensure the proper fuel/air mixture makes it to the engine. First, there’s the priming bulb: usually a clear, rubbery protrusion near the carburetor you can press. It will fill itself with fuel, injecting the fuel system with additional fuel as needed for starting.

You should also learn to use your engine’s manual choke feature properly, if it has one. Many newer engines have an automatic choke, and mowers generally have either a choke or a priming bulb, as they both perform the work of enriching the fuel/air mixture for starting your engine. Start your engine with the choke on, then move it to the opposite position once the mower is running properly. Leaving the choke on will stall or potentially damage the engine. Also, check to see if the tiny hole in your gas cap is clogged. That hole creates a vent to allow fuel to move down the fuel lines, and if it’s clogged, your engine will be starved of fuel.

Air filters

The Toidi/Shutterstock

Of course, when it’s time for things to blow up inside your engine’s cylinders, gas is only half of the story. Your choke (if you have one) tells the other half: You also need air to mix with the gas, and some mechanisms to help with the mixing. The choke makes the fuel/air mixture richer by restricting (temporarily) the flow of air through the carburetor. Once the engine is running, you should return the choke (and, thereby, the airflow) to normal. But there are a few possible reasons you might continue to have airflow problems.

The first is a dirty air filter. Like most parts of a lawn mower, the air filter is prone to becoming filthier than seems possible. This means it’s doing its job, and it also means the filter requires cleaning or replacing from time to time. A dirty air filter will cause an engine to misbehave in all manner of ways, including not starting easily or at all. Your mower has one or two filters, any of which may be either foam or paper. It’s usually better to replace a paper filter if possible, but otherwise tap it against a hard surface and blow it out gently from the inside with an air compressor.

Foam filters are a bit more involved. Start by tapping and blowing it out like a paper filter, then spray it thoroughly with a filter degreaser and allow to soak for 15 minutes. Rinse under clean running water and allow it to dry, and then apply a filter oil spray. To the extent it’s possible without damaging the filter, squeeze the filter to work the oil throughout. After a few minutes, reinstall the filter and wipe away any excess oil.

More air: carburetor

KPhrom/Shutterstock

Sometimes your fuel/air mix is off because the carburetor isn’t doing its job properly. In extreme cases, this could prevent the engine from starting. At that point, you must choose between cleaning and rebuilding the carburetor. Fortunately, these processes are mostly very simple. The standard process for cleaning a carb is to remove and clean (or replace) the air filter, then inspect the carburetor inside and out for stray debris. Finally, spray carburetor cleaner into the carburetor while the engine is running, per directions on the spray can.

If this doesn’t work — perhaps because the gum and gunk inside the carburetor is extreme as a result of age or being run with old gasoline — removing and rebuilding the carb isn’t as scary as it sounds. It’s basically a process of taking the carb off and then cleaning everything off of it that you can. It’s also a good idea to take some photos along the way, so you can be sure of how everything goes back together. Finally, just reassemble. Briggs & Stratton has a good online overview of this process.

If this makes you too nervous, try adding a cleaning mixture of 4 ounces Sea Foam Motor Treatment and 8 ounces gasoline to the tank. Remove the spark plug(s) and then prime and crank or rope-pull the engine to draw the mixture into the carb. Allow it to sit 24 to 72 hours, then run the engine per Sea Foam’s instructions.

Odds, ends, and tips

Focused Adventures/Shutterstock

There are a few other fairly common situations that can interfere with starting a mower. It’s never a bad idea to change your oil, but be sure to do it properly. Old oil, insufficient oil, overfilling with oil, or using oil that’s the wrong weight (viscosity) for the temperature outside can all contribute to difficult starting.

Keep your mower deck clean; an overabundance of grime and debris can slow blade rotation and hinder starting. Similarly, if you’ve run into something recently with your mower, inspect the mower deck to make sure the blades can rotate freely. A blade striking the deck can prevent the mower from starting altogether.

Finally, there’s the unpleasant business of the starter rope — that thing you yank on a mower with a recoil starter. There are two types of mower owners: those who have cursed the fortunes and questioned the character of mower manufacturers for inventing the recoil starter, and those who haven’t used a recoil starter at all. Common causes of starter rope problems include overfilling with oil and debris interfering with rotation in the mower deck, as mentioned above. Similar problems include bent mower blades and damaged mower deck shrouds. The cord may also be difficult to pull because the flywheel brake (controlled by a bar you must hold while using the mower) is stuck. Try loosening or tightening the cable, then repeatedly open and close the bar that engages the flywheel brake. If this doesn’t work, you might need professional assistance. If you feel up to it, Briggs & Stratton has flywheel brake replacement instructions. Similarly, a hydrolocked engine (one that has seized after getting water in the engine) will normally require professional help, unless you’re up for these steps from Garden Guides.

Problems that aren’t (exactly) problems

Virrage Images/Shutterstock

Sometimes you’ll hear that the cause of some problem is a feature and not a bug, but the distinction isn’t helpful if you can’t start your lawn mower. The best example of this is a mechanism called a “safety interlock” (or often “safety switch”), by which your mower won’t run because some other thing isn’t quite right. For example, riding mowers that won’t start unless you’re sitting in the seat. Some cars have interlocks that prevent you from operating them if you’ve had a few beers, but fortunately mowers don’t have this feature yet, as it would prevent about 90% of Saturday afternoon lawn mowing from happening at all.

The safety switches on most riding lawn mowers include a seat switch that will not allow the engine to run unless the seat is occupied; a PTO safety switch that might prevent the blades from turning in certain situations and prevent the mower from starting when (for example) the blades are engaged; a brake switch to keep the mower from starting unless the brake is applied; and a reverse switch, that prevents mowing. Obviously several of these can prevent an engine from starting if they malfunction.

It might be tempting to disable some or all of these safety switches. Don’t — they’re there for good reasons. Unless you’re handy with a multimeter and circuits, dealing with faulty safety switches might be another job for a professional.

Troubleshooting guide

Aleksandar Blanusa/Shutterstock

So, how do you know which of these problems is preventing your mower from starting? Let’s look at a few questions that will help you narrow down the most common problems and their solutions. If your mower is full of fuel but only runs for a few seconds, check the pinhole vent in your gas cap for obstructions. This could also be a sign of old gasoline. If the engine hasn’t been run in more than a month, treat the gas as suspect. You might also clean the carburetor and clean or replace the spark plug(s).

If your engine sounds like it’s cranking, but won’t fully turn over, you might have an electrical problem — possibly the starter. If you hear a clicking sound but nothing else, that similarly suggests starter, battery, or related problems. If you don’t hear anything at all when you turn the key, check the starter solenoid and its connections. This also might indicate issues with the battery, coil(s), ignition switch, or safety interlocks. Hearing nothing at all could also indicate that your mower is refusing to start because it is low on oil.

If the engine is cranking slowly, you probably have a failing battery. Check the battery and alternator. If your pull cord is difficult to pull, check that the flywheel brake is disengaged. Be sure you don’t have too much oil in the engine, and that it’s the correct weight for the season. Another sign the engine might be overfilled with oil is the presence of blue or white smoke when it does run. Black smoke, on the other hand, indicates the fuel mixture is too rich. Replace the air filter and check the choke mechanism.